BMW Electromobility.

The BMW Group has already put 1,000,000 electrified vehicles onto the road by 2022.

Sustainability in production, in equipment and in consumption. Our vehicles and their production show how we view our responsibility as a company in these areas. And how we assume this responsibility. Find out more about what we are doing – and all the things we are planning.

The BMW Group has already put 1,000,000 electrified vehicles onto the road by 2022.

The total energy consumption of the BMW Group in 2022 was 6.3 million MWh. That is 2.8% less energy consumed than the year before. Thanks to energy-saving measures, like switching over to LED lighting in 16 plants.

Just 0.32 t CO2 emissions were created in 2022 in the production of a BMW. Compared with the emissions from resource procurement and those that occur during use this is a small share. But it has a positive impact on the overall CO2 footprint of a vehicle.

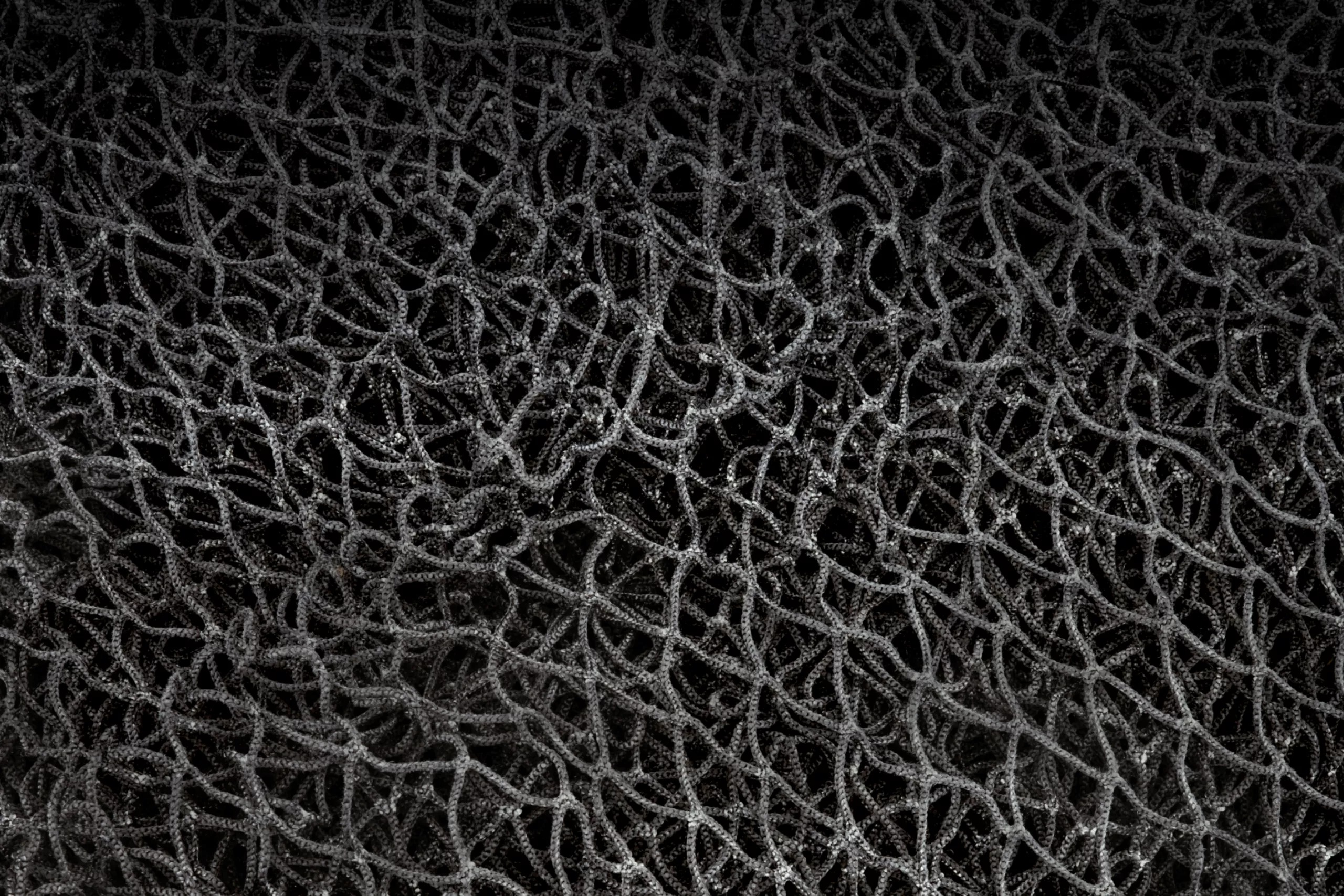

The floor panels in the BMW iX as well as the new BMW X1 and BMW i5 are made from a plastic thread derived from disused fishing nets, floor coverings and scrap from plastics production as its starting materials.

Recycled materials are used in many components of a BMW. The luggage compartment panelling in the BMW i5, for example, comprises up to 60% recycled plastic. In the guides for the bumpers, the substructure of the door panels, the windscreen panel cover and the frame of the front cowling of the BMW iX, this figure is even as high as 100%.

In cooperation with start-up companies, the BMW Group is developing innovative bio-based surfaces. The newly developed Deserttex™, for instance, is made up of pulverised cactus fibres and a bio-based polyurethane matrix. In this way, the avoidance of animal-based products can be combined with a reduction in CO2.

Explore the full range of electric vehicles from BMW alongside the BMW iX.

A focus on sustainability and customer proximity is what distinguishes the BMW Group. That's why we prefer to produce locally around the world - in compliance with uniform quality and safety standards.

The four wind turbines on the grounds of the BMW Group plant in Leipzig are each able to achieve a nominal output of 2.5 MW. They cover about one eighth of the electricity required in the plant. An intelligent storage farm in which up to 700 BMW i3 batteries are linked in a network stores surplus energy from the four wind turbines in times of surplus supply and feeds the electricity back into the grid when there is insufficient wind.

The solar power plant in the BMW Brilliance Automotive Ltd. Plant Dadong (Shenyang) is able to produce more than 21 MWh of renewable energy in 2022. To this end, its area has been increased by 110,000 m2 – equivalent to roughly 15 football pitches – to a total of 290,000 m2 during the course of the Shenyang site expansion.

Sustainability covers many aspects at BMW: from the inspection of our supply chains through to support for external programmes, we do everything to keep our ecological footprint as small as possible.

The BMW Group is the first German automobile producer to join “Business Ambition for 1.5 °C”. This includes our commitment to climate neutrality along the value-added chain until 2050. As a consequence, we are automatically a member of the UN “Race to Zero” programme. On the other hand, our long-standing membership of the “United Nations Environmental Programme” is yet another indication of how seriously the BMW Group takes sustainability.

The BMW Group seeks to bring cobalt mining and processing in line with its sustainability and internationally applicable labour standards. To this end, the BMW Group, together with a number of other partners, established 2018 the cross-industry initiative Cobalt for Development in order to improve the labour and living conditions of workers in small-scale cobalt mining in the Democratic Republic of Congo.

A multi-stage process secures our responsibility for the supplier network within all relevant divisions of the BMW group. Among the divisions in which we have introduced specifications for social and environmental standards are energy usage, logistics and the development of components, as well as in the contract-awarding process as a decision-making criterion as well as in supplier development. In order to implement these environmental and social standards, we are co-creators of the Responsible Supply Chain Initiative (RSCI) founded for this purpose and today we are already relying on electric trucks to supply the plants in some cases and are supporting initiatives aimed at organising the sea transport of vehicles to generate fewer emissions.